Silicon carbide (SiC) is a high-performance semiconductor material composed of pure silicon and pure carbon. With its exceptional thermal stability, high breakdown voltage, and superior thermal conductivity, SiC has become a crucial material in various industries, including modern electronics, automotive, energy, and aerospace. In recent years, the rapid growth of electric vehicles (EVs), renewable energy, and high-power electronic devices has further highlighted the value of SiC. This article explores the definition, applications, advantages, and manufacturing process of silicon carbide.

1. What is Silicon Carbide (SiC)?

Silicon carbide is a semiconductor material with a wide bandgap (~3.26 eV), offering superior electrical and thermal properties compared to traditional silicon (Si). It can be doped with different elements to form N-type (doped with nitrogen or phosphorus) or P-type (doped with beryllium, boron, aluminum, or gallium) semiconductors. Although SiC was discovered in the late 19th century, its widespread adoption in the semiconductor industry has only gained momentum in recent decades.

2. Major Applications of Silicon Carbide

Due to its outstanding properties, silicon carbide is widely used across multiple industries, including electronics, electric vehicles, and renewable energy systems.

2.1 Semiconductor & Electronics Industry

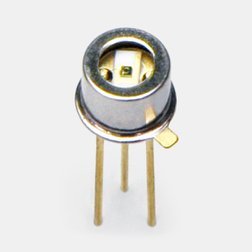

SiC is a key material for high-power electronic devices and is commonly used in MOSFETs, Schottky diodes, and power modules. Compared to conventional silicon (Si), SiC can withstand higher voltages (up to 10kV) and has significantly lower switching losses, making it ideal for efficient power conversion systems.

2.2 Electric Vehicles (EVs)

Silicon carbide holds great potential in the electric vehicle industry, particularly in inverters, charging systems, and battery management systems (BMS). SiC inverters can enhance the driving range of EVs while reducing the overall system size and weight. Additionally, SiC’s high thermal conductivity improves heat dissipation, increasing system reliability.

Industry Prediction: According to Goldman Sachs, adopting SiC technology could reduce the manufacturing cost of each EV by approximately $2,000, while improving charging efficiency by reducing power loss by 30%, increasing power density by 30%, and decreasing component count by 30%.

2.3 Solar Energy & Renewable Energy Systems

SiC plays a significant role in solar inverters, where its high-frequency switching capability can increase conversion efficiency by 2-3 times, reducing system size and lowering the cost of magnetic components. Additionally, SiC inverters are more durable than traditional silicon-based inverters, ensuring long-term stability in solar energy systems.

2.4 Data Centers & High-Performance Computing

Modern data centers require highly efficient power conversion technologies, and SiC helps reduce energy losses and improve system stability. The adoption of SiC technology enhances power management in data centers, leading to lower carbon emissions.

3. Advantages of Silicon Carbide

Compared to conventional silicon (Si), silicon carbide offers several key advantages:

- High thermal conductivity (120-270 W/mK) – Enhances heat dissipation in high-power devices.

- Low thermal expansion coefficient (4.0×10⁻⁶/°C) – Maintains stability in high-temperature environments, improving component reliability.

- High current density – Ideal for high-voltage and high-power applications such as electric vehicles and power grids.

- Low switching losses – Reduces energy loss and improves efficiency, particularly in >600V applications.

- Compact and lightweight – SiC components can reduce system losses by 50%, decrease volume by 300%, and lower overall costs by 20%.

4. Silicon Carbide Manufacturing Process

4.1 Acheson Method (Traditional Production Method)

The Acheson method is the earliest SiC production technique, involving the high-temperature reaction of silica (SiO₂) with carbon (such as coal or coke):

This method is suitable for large-scale, cost-effective SiC production but yields lower purity, typically used for industrial applications.

4.2 Lely Method (High-Purity SiC Single Crystal Growth)

The Lely method is the primary technique for producing high-purity SiC crystals. This method employs high-temperature sublimation, where SiC vaporizes at 2700°C and deposits onto a lower-temperature graphite substrate, forming high-purity SiC single crystals. This process is widely used in the semiconductor industry.

4.3 Chemical Vapor Deposition (CVD)

CVD is an advanced technique for producing high-precision SiC films and wafers. This method utilizes gaseous chemical precursors in a vacuum environment, enabling the deposition of high-purity 3C-SiC cubic crystal structures, which are extensively used in semiconductor applications.

5. Future Developments in the Silicon Carbide Industry

With the increasing demand for high-power, high-efficiency electronic devices, the market for silicon carbide is expanding rapidly. Major global semiconductor companies such as Wolfspeed, Rohm Semiconductor, and Silicon Labs are actively advancing SiC technology and expanding their product portfolios.

5.1 Wolfspeed

As the world’s largest manufacturer of SiC substrates, Wolfspeed offers a broad range of MOSFETs, Schottky diodes, and AEC-Q101 certified automotive-grade SiC components, driving the adoption of SiC in electric vehicles and industrial power systems.

5.2 Silicon Labs

Silicon Labs specializes in high-performance SiC solutions, focusing on battery management systems (BMS) and high-frequency power distribution, supporting the rapid development of the EV and renewable energy sectors.

5.3 Rohm Semiconductor

Rohm Semiconductor produces high-performance SiC MOSFETs and power modules to meet the growing market demand.

6. Conclusion

Silicon carbide (SiC) is rapidly gaining prominence due to its superior thermal conductivity, high breakdown voltage, low switching losses, and overall efficiency. It is a game-changing material in industries such as electric vehicles, renewable energy, data centers, and high-power semiconductors.

As technology advances and manufacturing costs decrease, SiC is expected to become a mainstream semiconductor material in the coming years. It will drive improvements in global energy efficiency, reduce carbon emissions, and foster more sustainable technological innovations.

If you are interested in silicon carbide technology, stay updated with the latest industry trends.