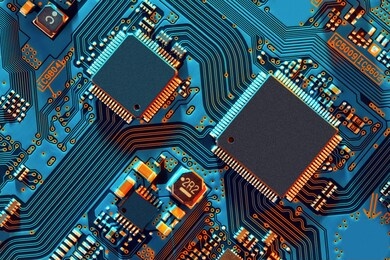

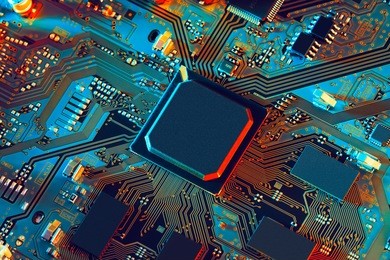

An Integrated Circuit (IC) chip, often referred to simply as a microchip, is a fundamental component of modern electronics. It is a small semiconductor device that contains a multitude of electronic components such as transistors, resistors, and capacitors, all integrated into a single silicon wafer. These components are interconnected to perform various functions, making IC chips the “brains” of many electronic devices.

IC chips come in a wide range of types and sizes, from the simple logic gates used in basic digital circuits to highly complex microprocessors that power computers and smartphones. They are responsible for processing data, executing instructions, and controlling the behavior of electronic devices.

The invention of the IC chip revolutionized the electronics industry by enabling the miniaturization of electronic components and increasing the efficiency and performance of electronic devices. IC chips have become an essential part of everyday life, playing a critical role in powering the technology we rely on for communication, entertainment, and countless other applications.

In this article, we are going to explore how an IC chip is made. Creating an IC chip is a complex process involving several key steps. It starts with a silicon wafer, which undergoes precision patterning, etching, and doping to create the desired circuits and components. Thin insulating films and metallization layers are added to connect and protect these elements. Finally, the chip is encased in a protective package. Quality control ensures each chip meets specifications. The result is a tiny marvel that powers our electronic devices, with millions or even billions of transistors on a single silicon chip, guiding everything from your smartphone to your car’s advanced systems.

Now, let’s see the details of these processes.

Silicon, the Miracle Material

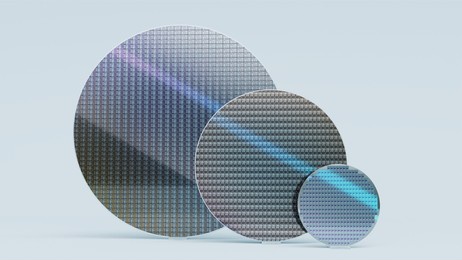

The journey of creating IC chips begins with silicon, a semiconductive material renowned for its properties. Silicon wafers serve as the foundation for crafting these microcircuits. The process commences with pure silicon, which undergoes several critical transformations.

The first pivotal step involves growing a silicon ingot using the Czochralski process. Here, a minute seed crystal is immersed in molten silicon and gradually pulled upward, facilitating the formation of a single, substantial silicon crystal. These large crystals are then sliced into ultra-thin wafers, which are poised to be shaped into microchips.

Patterning: Shaping the Brain

Patterning is the art of defining the chip’s intricate circuitry, essentially giving it its “brain.” This process is a meticulously controlled masterpiece. To execute it, a layer of photosensitive material, known as a photoresist, is meticulously spread across the silicon wafer. Following this, ultraviolet light is projected through a mask, imprinting the desired pattern onto the photoresist. This pattern acts as the blueprint for the chip’s circuitry.

Etching: Carving the Circuit

With the pattern in place, the next step is etching away the excess silicon material, much like an artisan sculpting a masterpiece. The preferred method here is dry etching, where a plasma of reactive gases is employed to selectively remove the unwanted silicon. What remains after this process is the foundational structure of the IC chip, complete with all the essential components.

However, this is just the start of the chip’s transformation. To bring its functionality to life, we need to add an extra layer of complexity.

Ion Implantation: Adding Functionality

To make the transistors and other components on the chip work, we introduce dopants – minute atoms of other materials like phosphorus or boron. These dopants are strategically implanted into the silicon to modify its electrical properties. The depth and concentration of these dopants are meticulously controlled to ensure the chip operates as intended. It’s akin to fine-tuning an instrument but on an atomic level.

Thin Films: Insulating and Connecting

The journey continues with the deposition of thin films onto the silicon wafer. These thin films serve multiple functions – insulating, conducting, and protecting the underlying layers. They form the pathways for electrical connections between various parts of the chip. These films are incredibly thin, often measured in nanometers, and they play a critical role in ensuring the chip’s overall performance.

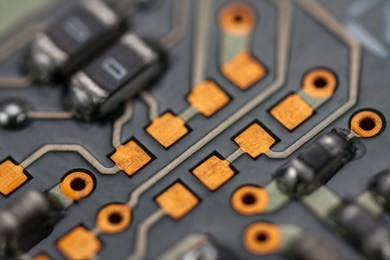

Metallization: Wiring the Chip

In the process of metallization, metal layers are deposited and patterned onto the chip to create the interconnections between different parts of the circuit. These metal traces, often made of materials like aluminum or copper, act as the wiring that allows signals to flow between the various components of the chip.

Packaging: Protecting the Core

Now that our microchip is ready, it needs to be shielded from the outside world. It is sealed within a protective package, typically made of plastic or ceramic, with tiny pins or solder balls for connections. This package serves the dual purpose of safeguarding the chip and ensuring it remains at an optimal operating temperature.

Quality Control: Ensuring Perfection

No chip leaves the production line without undergoing a rigorous testing process. Each chip is meticulously examined for defects, ensuring that all components function as intended and verifying that they meet the necessary specifications. This stringent quality control is crucial in guaranteeing that the chip you receive is flawless and ready to power your devices effectively.

The creation of IC chips is a testament to human ingenuity, involving countless steps and a deep understanding of materials and technology. It’s a witness to the relentless pursuit of miniaturization and efficiency that powers the modern world.

In conclusion, the process of making IC chips is a marvel of engineering and science, involving precise steps and a profound understanding of materials and technology. If you have more questions or want to explore specific aspects of IC chip manufacturing, feel free to reach out.