What is FFC cable?

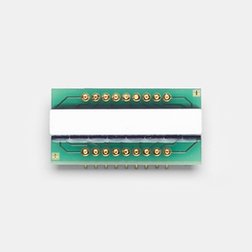

FFC (Flexible Flat Cable) is a flat ribbon cable with contacts at both ends. FFC consists of multiple parallel conductors embedded in a flat insulating layer. Usually, the conductors of FFC appear as parallel lines side by side on the insulating layer. FFC is mainly made by etching copper conductors on an insulating substrate. During the production process, the structure of the substrate and the conductors remain consistent and have good flexibility.

What is FPC cable?

FPC (Flexible Printed Circuit) is a flat circuit board in the form of a cable with contacts at both ends and circuits added along the cable. FPC is a cable with circuit patterns printed on a flexible insulating material. These circuit patterns are usually made by photolithography, which has high precision and flexibility. The manufacturing process of FPC involves depositing, photolithography, and etching circuit patterns on a flexible substrate, usually using thin film technology, which can achieve complex circuit designs.NOTHING

Distance between FFC cable and FPC cable

Regardless of which cable type you choose, you will need to select a pitch/spacing. Pitch is the distance between the conductors at each end of the cable (center to center). Standard pitches include .5mm, .635, .8mm, 1.0mm, 2.54mm (.1 inch), and many others.

Design and manufacturing of FFC and FPC

FFC cable: Flat flexible cable ffc design is relatively simple and is mainly used in applications that require fewer wires. Its design includes determining the number of wires, spacing, and flatness. The production process involves etching the wires into a flexible insulation layer, which is then folded into a flat cable shape. The manufacturing cost of FFC is relatively low.

FPC cable: FPC supports more complex circuit designs, including multi-layer circuits and complex connection patterns. It can realize more circuit functions and support high-density integration. The manufacturing process of FPC includes multi-step pattern transfer and circuit pattern formation, which usually involves complex processes such as photolithography, chemical deposition, and etching. Its manufacturing cost is high, but it can achieve higher circuit density and smaller size.

Performance of FFC Cable and FPC Cable

FFC Cable: FFC has good flexibility and is suitable for applications that require bending and folding, but usually needs to maintain a larger bending radius. The electrical performance of FFC is relatively simple and is suitable for low-speed or medium-speed data transmission. The quality of its signal transmission may be affected by the wire spacing and signal interference.

FPC Cable: FPC provides higher flexibility and a smaller bending radius, suitable for use in space-constrained applications. FPC supports higher data transmission speeds and more complex circuit designs. Due to its sophisticated manufacturing process, FPC can provide better electrical performance and lower signal interference.

What can FFC be used for?

FFC (Flexible Flat Cable) is a ribbon cable named for its wide and flat structure. They usually use straight connectors and do not require additional components. FFC cables are made of plastic film, and multiple metal connectors are bonded to the film. The spacing between the connectors is called “pitch”. This structure allows FFC cables to take up less space than round cables, provide higher flexibility, have better EMI/RFI suppression, and solve the problem of wire coupling. FFC cables are often used in high-density electronic systems, especially in applications that require high flexibility, such as connecting mobile print heads, folding mobile phones, or in places where space and weight are limited. Please provide your specific requirements, including the number of connectors, pitch, length, and terminal type, and our experienced team will provide you with a quote for custom-designed electronic components.

What can FPC be used for?

Flexible printed circuit (FPC) is a typical application of flexible electronics, which consists of a flexible polymer substrate with a conductive circuit printed on its surface and then sealed with a protective polymer coating. FPC is not just a connector, it is actually a circuit board that is lighter, thinner and more flexible than traditional rigid circuit boards. This flexibility enhances the durability and reliability of FPC, making it an ideal choice for highly flexible electronics, especially in applications where weight and/or space are limited, such as flexible solar cells in consumer electronics, hearing aids, and satellites.

FAQ

1. What is Type 1, Type A or Type BD FFC?

It is an FFC with contacts on the same side.

2. What is a Type 2, Type D, or Type AD FFC?

It is an FFC with contacts on opposite sides.

3. Can I block FFC?

Yes, we can add a layer of shielding tape to the FFC. Custom FFCs can even have the pins connected to the shield.

4. What is the purpose of ribbon cable?

FFC ribbon cables are used for straight-through board-to-board connections.

5. What does the “pitch” of FFC or FPC mean?

It refers to the distance between the center of one conductor and the center of its adjacent conductor.

6. What is an FFC/FPC connector?

The FFC connector is used to connect flexible flat cables (FFC). FFC cables are flat cables in a ribbon shape, usually consisting of a plastic film and multiple metal connectors bonded to the film.

The FPC connector is used to connect flexible printed circuit boards (FPC). FPC is a circuit board made of a flexible polymer substrate with a conductive circuit printed on its surface.

7. What is the difference between FFC and FPC?

FFC and FPC are often confused because they look very similar, are flat, and both transmit data. However, they are very different.

FFCs usually must have straight-through conductors and the pinout is 1-to-1 or 1-n.

FPCs, on the other hand, can have a variety of pinouts because they can be multi-layered and the conductors can cross each other. FPCs can also be impedance controlled, which makes them a better choice for data cables such as LVDS. FPCs can also be designed with bends and angles, not just rectangular. FFCs and FPCs each have their own characteristics and applicable scenarios. FFCs are more suitable for cost-sensitive applications that require simple cable connections and moderate flexibility. FPCs, on the other hand, are suitable for applications that require complex circuits and high performance, providing greater design flexibility and electrical performance. Which cable to choose depends on the specific application needs, performance requirements, and budget constraints.

For purchase and consultation information, please contact: ciclibattery.com