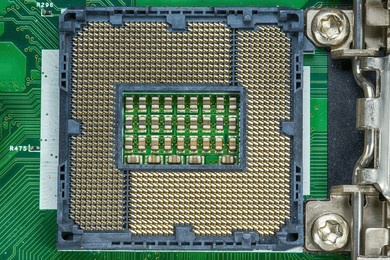

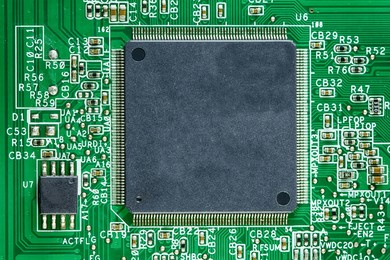

An integrated circuit (IC) chip, often referred to as a microchip, is a miniature electronic circuit that incorporates various components, including transistors, resistors, and capacitors, on a small semiconductor wafer. IC chips serve as the brains behind our electronics, from smartphones to laptops and even your car’s engine control unit. In this article, we are going to explore the exciting world of testing IC chips.

The Significance of Testing

IC chips are at the heart of almost every electronic device we use, and ensuring their reliability and functionality is paramount. Manufacturing defects, external factors, and even natural wear and tear can affect IC chips. Testing them is essential to guarantee their performance and prevent potential malfunctions.

Process of Testing IC Chips

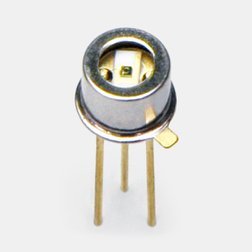

Visual Inspection

Visual inspection is the first and simplest step in testing IC chips. It involves a close examination of the chip’s external features to detect any visible defects like cracks, scratches, or irregularities. While it doesn’t assess the internal functionality, visual inspection can quickly weed out chips with obvious issues.

Functional Testing

Functional testing assesses the IC chip’s performance by applying specific input signals and evaluating the output. This process verifies that the chip performs its intended functions as designed. It’s like putting the chip through its paces to see if it delivers.

Electrical Testing

Electrical testing dives deeper into the chip’s functionality. This involves measuring its electrical characteristics, such as voltage, current, and frequency. By comparing these measurements with expected values, testers can identify any deviations that might indicate a problem.

Thermal Testing

Heat can be a chip’s enemy, and thermal testing is designed to assess how well a chip handles temperature fluctuations. It involves exposing the IC chip to varying temperatures to ensure it can operate within specified thermal limits.

Environmental Testing

Electronics don’t always live in cozy environments. They might be subjected to humidity, dust, and vibrations. Environmental testing simulates these conditions to ensure the chip remains reliable even in adverse situations.

X-Ray Testing

For a peek inside the chip without breaking it open, X-ray testing is invaluable. It reveals any internal defects or soldering issues that might not be visible from the outside.

Burn-In Testing

The burn-in test, as the name suggests, involves running the chip at elevated stress levels for an extended period. This process helps identify any weak components that might fail under normal operating conditions.

Final Inspection

Before an IC chip is ready for action, a final inspection is performed, ensuring it meets all quality standards. This includes a review of previous test results and a final visual check.

Conclusion

Testing IC chips is a crucial part of the manufacturing process, assuring that the heart of our electronic devices beats steadily. These tests guarantee that the chips can withstand the rigors of daily use and adverse conditions. If you are interested in IC chips, you can contact us by filling out the form on your right.