The newer high-end and midrange vehicles traveling along the highway are likely utilizing Power over Coax (PoC) cable assemblies to transmit the power and data needed for high-bandwidth electronic systems, and to reduce wiring complexity and overall weight. Even lower-cost vehicles are beginning to adopt PoC technology, as infotainment and driver-assistance applications move down the market.

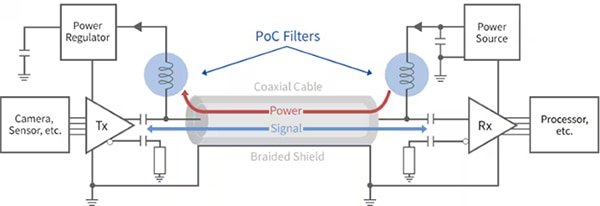

Backup cameras and automatic emergency braking are now required in all vehicles for the U.S. market, regardless of price. PoC cabling provides a simpler, more cost-effective way to transmit both power and data over a single cable (Figure 1). By reducing weight, the technology can help improve the fuel efficiency of gas-fueled vehicles and the range of electric vehicles (EVs). Simpler cable assemblies can also help decrease time and labor for installation and maintenance, save on the cost of materials, and scale across a manufacturer’s product line.

However, combining signals and power within a single coaxial cable is inherently noisy, so automotive PoC applications need high-impedance filtering inductors to ensure the operational reliability of complex electronic systems. Proper impedance matching is essential to avoid voltage drops, power loss, and data degradation that could adversely impact vehicle operation.

Multilayer inductors are increasingly indispensable for their ability to ensure clean signal transmissions. They provide high inductance and impedance in very compact form factors that meet space-saving demands as automotive manufacturers increase on-board electronics.

How PoC aligns with automotive application requirements

PoC streamlines the delivery of power and data over a single cable, saving on material costs with fewer components and reducing potential points of failure.

The technology can more readily scale to support additional features, which is critical as assemblers scramble to add more sensors and other electronics for infotainment and safety, including ever-more sophisticated advanced driver assistance systems (ADAS). High-end vehicles are moving beyond mandates to offer premium features such as Level 2 autonomous driving, 360-degree camera views, and automated parallel and perpendicular parking.

This requires the ability to handle high-speed data transmission, high-resolution video, and real-time communication. The high-bandwidth, high-frequency capabilities of PoC are critical in the implementation of advanced vehicle systems that increasingly rely on multi-sensor fusion, 5G connectivity, centralized computing architectures, and edge computing capabilities. PoC can support auto industry standards such as FPD-Link III with up to 4 Gbps per link and automotive Ethernet transmission up to 10 Gbps.

Automotive applications must be designed to meet stringent standards, particularly when it comes to electromagnetic interference (EMI) from the high-frequency sources in a typical vehicle, such as ignition systems and electric motors. EMI noise could interfere with essential safety and infotainment systems that help motorists avoid backup collisions, stay in lanes, and slow or stop when vehicles, pedestrians, or other obstacles are in their path.

Shielded coax provides some protection from EMI, but because PoC transmits both power and data signals, applications require filters to prevent crosstalk and potential system instability. A capacitor on the signal line side is used to block current from the DC power supply, and a filter inductor on the power supply line will prevent broadband signal interference.

Filter inductors on the power line suppress noise and ensure signal integrity by blocking interference while allowing the DC current to flow. They are complemented by surface-mounted chip beads that suppress EMI, minimize crosstalk, and provide localized filtering.

Chip beads and filter inductors work together to ensure the seamless transmission of power and high-frequency data signals over a single coaxial cable. Each component plays a complementary role in managing noise and maintaining signal integrity. This is crucial in ensuring clean power delivery and stable data communication, which is essential for the reliability and efficiency of PoC automotive applications.

The role of inductors in PoC systems

Standard coil-based inductors can be used to block high-frequency data signals from the power line while allowing DC power to pass, but they can be bulky and perform poorly with the high-frequency range required for PoC applications. A typical PoC filter would consist of four inductors together with chip beads, taking up valuable space on a printed circuit board (PCB).

Multilayer inductors are highly compact and better suited to the space-constrained needs of automotive applications. They are formed by stacking layers of conductive and insulating materials to form a compact monolithic structure, making them ideal for use in automotive systems.

When selecting an optimal multilayer inductor, product designers must balance performance, size, and reliability to ensure efficient power delivery and data integrity. High-frequency data signals in PoC systems require inductors with consistently high impedance over wide frequency ranges, typically in the MHz to GHz range, to suppress noise effectively. Low DC resistance (DCR) is also crucial to minimize power losses, especially for applications such as EVs.

Designers should consider the noise environment, and may decide to pair multilayer inductors with chip beads for enhanced EMI suppression. One multilayer inductor and two chip beads could replace the four-inductor combination mentioned earlier, considerably reducing the required PCB area.

Multilayer inductors for PoC applications are designed to meet stringent automotive standards, such as AEC-Q200, and provide superior EMI suppression at high frequencies. They are produced using advanced processes that are scalable for high-volume automobile production needs.