SMD is an electronic component mounted on the surface of a printed circuit board, that is, a surface mount device, which is a technology for mounting electronic components directly on the surface of a printed circuit board (PCB). Compared with traditional through-hole mounting technology, SMD technology does not require punching holes in the circuit board, which allows the circuit board to be designed more compactly and the density of components to be higher. Compared with traditional through-hole components, SMD components have obvious advantages. First, they are smaller and lighter, which helps to design more compact and portable electronic devices. Secondly, SMD components can be arranged on both sides of the PCB, improving circuit density and supporting more complex designs. Finally, the automated installation process of SMD components can reduce manufacturing costs and improve production efficiency. Therefore, SMD can also be called SMC, which is a Surface Mount Component. SMD has a variety of packaging forms, most of which are standardized, which also makes automated PCB assembly a reality and easier.

SMD construction

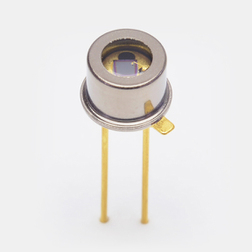

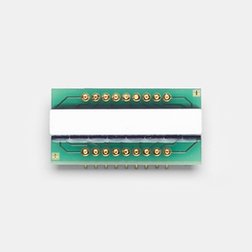

SMD devices usually have a smaller size and a simplified pin structure. Their pins are located on the side or bottom of the device and are connected to the pads on the circuit board through solder paste. Common SMD devices include resistors, capacitors, integrated circuits (ICs), transistors, etc.

Printing solder paste: First, print the solder paste on the pads of the circuit board.

Patch: Use an automatic patch machine to place the SMD device on the solder paste, ensuring that the device is aligned with the pad.

Reflow soldering: The entire circuit board is sent into the reflow oven, and the solder paste is melted by heating to form a firm solder joint with the device pins.

Inspection and testing: After soldering is completed, inspection and testing are carried out to ensure that all connection points are reliable and correct.

Basic types of SMD components

Resistance

Resistance is an important concept in electricity, used to describe the degree of resistance encountered when current flows in a circuit. Its unit is ohm (Ω). The size of the resistance depends on factors such as the material, length, cross-sectional area and temperature of the conductor.

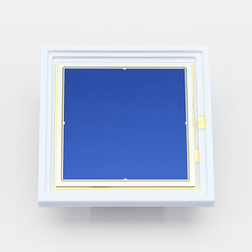

Capacitors

A capacitor is an electronic component used to store electrical charge and provide voltage balance in a circuit. It consists of two conductors (usually metal plates) separated by an insulating material (called a dielectric). The basic function of a capacitor is to store and release electrical energy, and it is widely used in electronic circuits to smooth power supplies, filter signal noise, store charge, etc. Capacitors are a basic type of SMD component, and they are used in circuits to store and release electrical energy, similar to a temporary battery. Capacitors are widely used in applications such as filtering noise, stabilizing voltage, and storing energy.

Inductors

Inductors are another type of SMD component that play an important role in electronic circuits. They function by storing energy in a magnetic field. When current flows through the inductor, they are mainly used in analog circuits and power supplies to filter high-frequency noise and stabilize the current.

Diodes

There are many types of SMD diodes, each with unique characteristics and applications. Here are some common types of SMD diodes and their characteristics

Rectifier diodes: This type of diode is used to convert alternating current (AC) to direct current (DC). Rectifier diodes have high current handling capabilities and high reverse voltage tolerance, making them suitable for use in power circuits.

Schottky diodes: Known for their low forward voltage drop and fast switching speed. Schottky diodes are particularly suitable for high-frequency applications such as radio frequency (RF) circuits and switching power supplies.

Zener diodes: Used for voltage regulation, they have a specific breakdown voltage, and once this voltage is exceeded, they begin to conduct in the reverse direction. Zener diodes are able to maintain a constant voltage across their terminals and are widely used for voltage stabilization in electronic circuits.

Light Emitting Diode (LED): A diode that emits light when current flows through it. SMD LEDs are used in a wide range of applications, from indicator lights to display panels, with a variety of brightness and color options.

Triodes, another important electronic component, consist of three electrodes: base, collector, and emitter. SMD transistors are widely used in various electronic devices. Compared with traditional through-hole transistors, they have smaller size and higher integration.

Each type of diode has its advantages and applicable scenarios. The choice of which diode usually depends on the requirements of the specific application. For example, rectifier diodes are suitable for power circuits that need to handle high currents, while Schottky diodes are more suitable for high-frequency applications.

Transistor

A transistor is a semiconductor device used to amplify or switch electronic signals. It consists of three layers of semiconductor material, usually called the emitter, base, and collector. The basic function of a transistor is to control the flow of current and adjust the output current according to the changes in the input signal, thereby achieving signal amplification or switching.

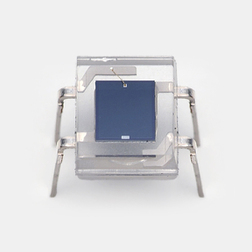

Integrated Circuit (IC)

An integrated circuit (IC) is an electronic device that integrates multiple electronic components (such as transistors, resistors, capacitors, etc.) on a small semiconductor chip. By combining these components on a single chip, it makes the circuit more compact, reliable and efficient. Integrated circuits are widely used in various electronic devices, including computers, mobile phones, televisions and household appliances.

Advantages of SMD:

- Space efficiency: SMD is smaller, allowing higher component density on PCB, making the device more compact.

- Lightweight: SMD is light, which contributes to overall lightweight.

- Improved electrical performance: Short leads reduce signal attenuation and improve high-frequency performance.

- Better thermal management: Efficient heat dissipation ensures component reliability.

- Automatic assembly: Compatible with automated assembly processes, enabling faster and more precise production.

- Cost-effectiveness: Reduces material waste, production time and labor costs.

- Design flexibility: Provides greater layout freedom and supports the miniaturization of complex systems.

- Reliability: Provides secure connections, withstands mechanical stress, and improves product reliability.

Disadvantages of SMD:

- Higher complexity: Requires specialized manufacturing technology and equipment.

- Repair and rework challenges: Difficult to repair or replace, especially without the right tools and expertise.

- Sensitive to handling: Small size makes it more sensitive to electrostatic discharge (ESD) and improper handling.

- Limited power handling capabilities: Due to size and heat dissipation capabilities, some SMDs are limited in handling high-power applications.

Applications

SMD technology is widely used in various electronic products, including:

- Consumer electronics: such as mobile phones, TVs, computers, etc., SMD technology makes these products more sophisticated and complex in size and function.

- Automotive electronics: A large number of SMD devices are used in modern cars to implement various functions, such as control systems, entertainment systems and safety systems.

- Medical equipment: SMD technology provides high-precision and reliable components in medical equipment, such as portable monitoring equipment and diagnostic instruments.

- Communication equipment: In wireless communication and network equipment, SMD components can support high-speed data transmission and high-frequency signal processing.

Soldering SMD Component Methods

- Reflow soldering: Suitable for most SMD components. Apply solder paste to the PCB, place the SMD components, and heat through a reflow oven until the solder paste melts to form solder joints.

- Wave soldering: Although traditionally used for pin components, it can also be used with specialized equipment and is suitable for mass production.

- Manual soldering: Suitable for prototyping or small batch production, using a soldering iron and solder wire or solder paste, done manually.

- Laser welding: A high-precision soldering method used for applications with special requirements.

Conclusion

As one of the core technologies of modern electronic manufacturing, SMD technology has played an important role in many fields. Its high efficiency and compactness enable electronic products to achieve more complex functions in a smaller volume. With the continuous advancement of technology, SMD will continue to promote the development of the electronics industry and bring more innovative and intelligent electronic products.

For purchase and consultation information, please contact: emi-ic.com