A thermistor is a resistor device whose resistance changes with temperature. This change can be linear (as in certain types of thermistors) or nonlinear (as in common NTC and PTC thermistors). Thermistors are typically made from oxides, metallic compounds, or semiconductor materials, and their resistance increases or decreases with temperature. This characteristic enables thermistors to be widely used in various applications such as temperature measurement, temperature compensation, control systems, and electronic devices.

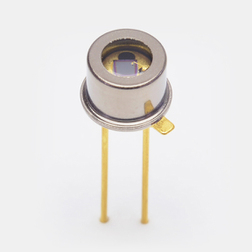

The composition of thermistor:

The relationship between the resistance of a thermistor and temperature primarily depends on the composition of its materials. Manufacturers typically determine this characteristic with high precision, as it is one of the most important features for buyers. Thermistors are made from metal oxides, binders, and stabilizers, which are pressed into wafers, then cut into chip sizes, retaining their disk shape or formed into other shapes. The precise proportions of these composite materials determine their resistance/temperature “curve”. Manufacturers usually control this ratio very precisely because it determines how the thermistor operates.

Types of Thermistors:

NTC thermistor (Negative Temperature Coefficient Thermistor):

The resistance of an NTC thermistor decreases as the temperature increases. Common materials include nickel oxide (NiO) and manganese copper (MnCu). This type of thermistor is widely used in temperature measurement and control, such as ambient temperature monitoring and temperature compensation of electronic equipment.

PTC thermistor (Positive Temperature Coefficient Thermistor):

The resistance of a PTC thermistor increases as the temperature increases. Common materials include silicon (Si), nickel sulfide (NiS) and polymers. They are mainly used in current limiting, power protection and overheat protection circuits, which can limit current or cut off the circuit when the temperature rises.

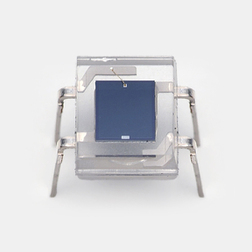

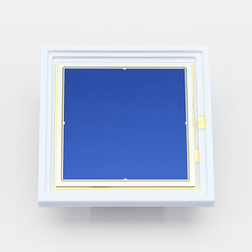

Precision thermistor:

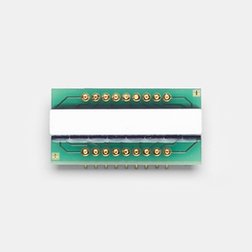

This type of thermistor has higher accuracy and stability and is usually used in applications that require high-precision temperature measurement and control, such as medical equipment and laboratory instruments. Surface mount thermistor: This type of thermistor is designed to fit surface mount technology (SMD) for easy integration into the miniaturized design of modern electronic devices.

Each type of thermistor has its specific application scenarios and advantages. Choosing the right type depends on the specific circuit design requirements and temperature control goals.

Temperature range, accuracy and stability:

Thermistors have very high accuracy, typically between 0.05°C± and 1.5°C±, but their effective operating temperature range is limited to approximately 50°C. Most thermistors operate from 0°C to 100°C. Class A thermistors offer the best accuracy, while Class B thermistors are suitable for applications where less precise measurements are required. Once manufactured, thermistors are chemically stable and their accuracy does not degrade significantly over time.

How is a thermistor wired?

Wiring a thermistor is very simple. Most come with a two-wire connector. The same two wires that connect the thermistor to its excitation source can be used to measure the voltage across the thermistor.

Common applications for thermistors:

Temperature measurement and control: The most common application is as a temperature sensor, measuring the ambient temperature or the temperature inside an electronic device. NTC thermistors are particularly suitable for this application because their resistance value changes linearly with increasing temperature, providing a simple and economical temperature measurement solution.

Temperature compensation: In various electronic devices and circuits, temperature changes may affect their performance and accuracy. By using a thermistor as a temperature compensation element, the operating point of the circuit can be adjusted to ensure stable performance under different temperature conditions.

Current limiting and overheating protection: PTC thermistors are widely used in current limiting and overheating protection circuits. When the current exceeds the set value or the ambient temperature rises to an unsafe level, the resistance value of the PTC thermistor will increase significantly, thereby limiting the current or cutting off the circuit to protect the equipment from damage or the risk of fire.

Power supply stability: In power supply circuits, thermistors can be used to stabilize the power supply output, especially in environments with large temperature changes. By monitoring and adjusting the resistance value of the thermistor, a more stable power output can be achieved.

Automotive electronic systems: In the automotive industry, thermistors are used in engine management systems, air conditioning controls, seat heating systems, etc. to help monitor and control the temperature of various components to improve efficiency and comfort.

Medical equipment: In medical equipment, thermistors are used to monitor and control the temperature of the equipment to ensure that the equipment operates within a safe and stable operating temperature range to protect the patient and the equipment itself.

For more information, please contact us at: emi-ic.com