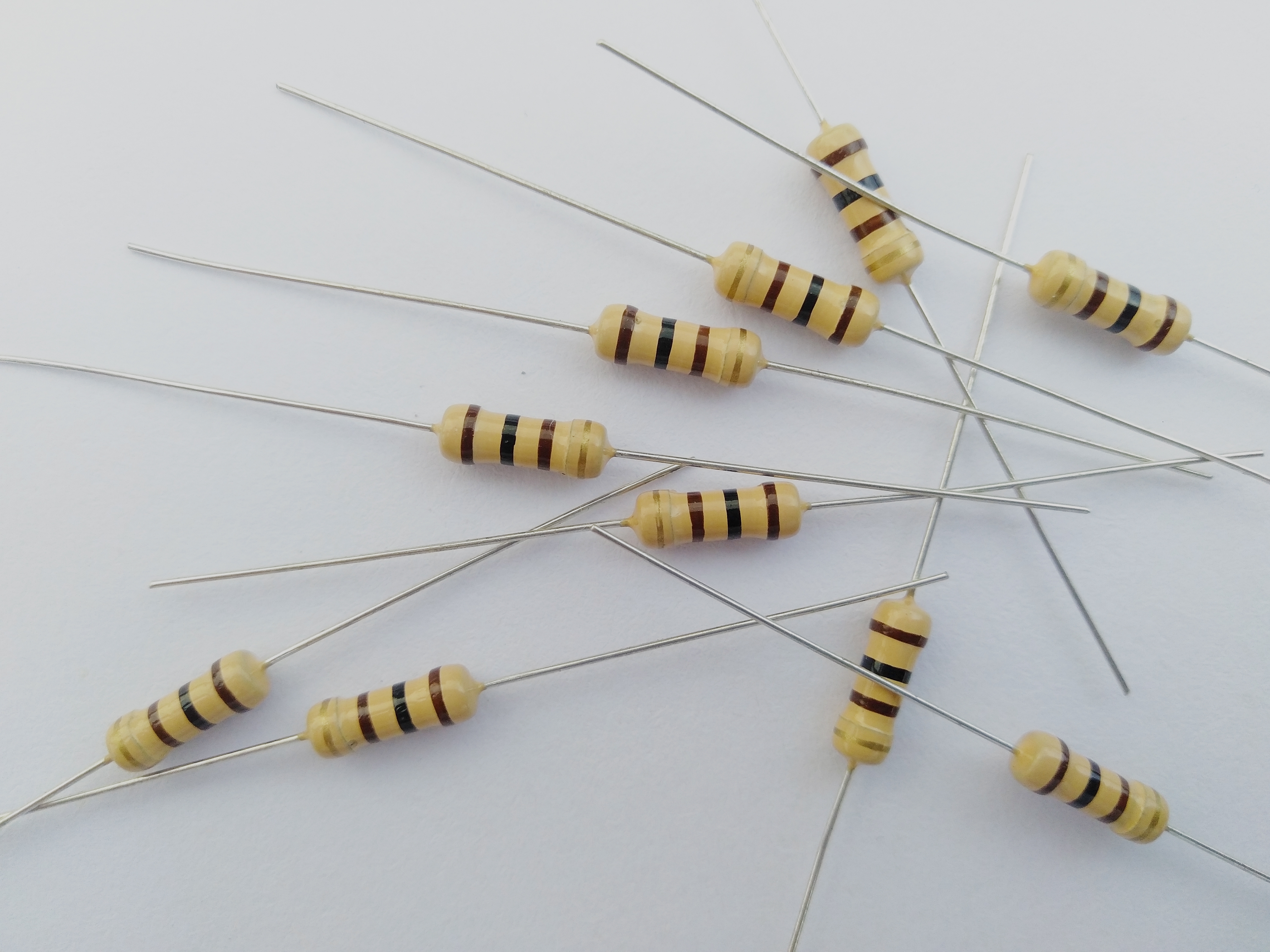

A resistor is an essential passive electronic component used in electrical and electronic integrated circuits. Its primary function is to impede or limit the flow of electric current, providing resistance to the flow of electrons. Resistor values are measured in ohms and determine the amount of opposition offered to the current. They come in various shapes and sizes, including axial leaded, surface mount, and network configurations. Resistors have numerous applications in electronics. They are used to control current, divide voltage, adjust signal levels, terminate transmission lines, and generate heat. By incorporating resistors into circuits, engineers can tailor and fine-tune the behavior of electronic systems.

Resistors play a crucial role in maintaining the stability and reliability of electronic circuits by preventing excessive current flow and protecting sensitive components from damage. With their wide range of values and power ratings, resistors enable precise control over the flow of current in diverse applications, making them indispensable components in modern electronics.

Resistors are typically made from materials with high resistivity, such as carbon composition, metal film, metal oxide, and so on. Here, we will mainly talked about the following 5 types of resistive material used in resistors.

- Carbon Composition: Resistors made with carbon composition consist of a mixture of carbon powder and a binder material. They are known for their stability, low cost, and wide resistance range. However, they have limitations in terms of precision and temperature stability.

- Metal Film: Metal film resistors have a thin layer of metal alloy (usually nickel-chromium or tantalum nitride) deposited onto a ceramic substrate. They offer better precision, stability, and lower noise compared to carbon composition resistors. Metal film resistors are widely used in applications that require high accuracy and stability.

- Metal Oxide: Metal oxide resistors are made by depositing a thin layer of metal oxide (such as tin oxide or ruthenium oxide) onto a ceramic substrate. They provide higher power ratings, better stability in high-temperature conditions, and lower noise compared to carbon composition resistors. Metal oxide resistors are commonly used in power electronics applications.

- Thick Film: Thick film resistors are created by screen-printing a resistive paste containing metal alloys onto a ceramic substrate. The paste is then heated to form a thick resistive layer. Thick film resistors offer a balance between cost, precision, and stability. They are often used in consumer electronics and general-purpose applications.

- Wirewound: Wirewound resistors are constructed by winding a resistive wire (usually made of a nickel-chromium alloy) around a ceramic or fiberglass core. They provide high power handling capabilities, excellent precision, and low temperature coefficient of resistance (TCR). Wirewound resistors are commonly used in precision measurement and high-power applications.

In summary, the choice of resistive material used in resistors plays a crucial role in determining their performance characteristics. Carbon composition resistors offer a wide resistance range and affordability but may lack precision and temperature stability. Metal film resistors provide better accuracy, stability, and lower noise levels. Metal oxide resistors excel in high-temperature environments and power applications. Thick film resistors strike a balance between cost, precision, and stability. Wirewound resistors offer high power handling capabilities and excellent precision. By selecting the appropriate resistive material, engineers can tailor resistors to meet specific requirements for various electronic applications. If you have any questions and want to get more information about resistors, don’t hesitate to contact us.